From Tracks to Rollers: Exploring High-Quality Undercarriage Parts for Every Demand

From Tracks to Rollers: Exploring High-Quality Undercarriage Parts for Every Demand

Blog Article

Maximize Efficiency With Sturdy Undercarriage Components

In the world of hefty machinery and tools, the role of undercarriage components is paramount in ensuring optimal efficiency and durability. The efficiency and efficiency of these elements can significantly affect the overall procedure of equipment, making the choice of resilient undercarriage components an important decision for supervisors and drivers alike. By discovering the complex relationship in between toughness and performance in undercarriage parts, a deeper understanding of the subject emerges, clarifying the crucial elements that drive operational success. As we browse through the intricacies of undercarriage long life, maintenance, and part selection, an extensive exploration awaits to unveil the key strategies for attaining peak performance in heavy-duty applications.

Advantages of Using Resilient Undercarriage Parts

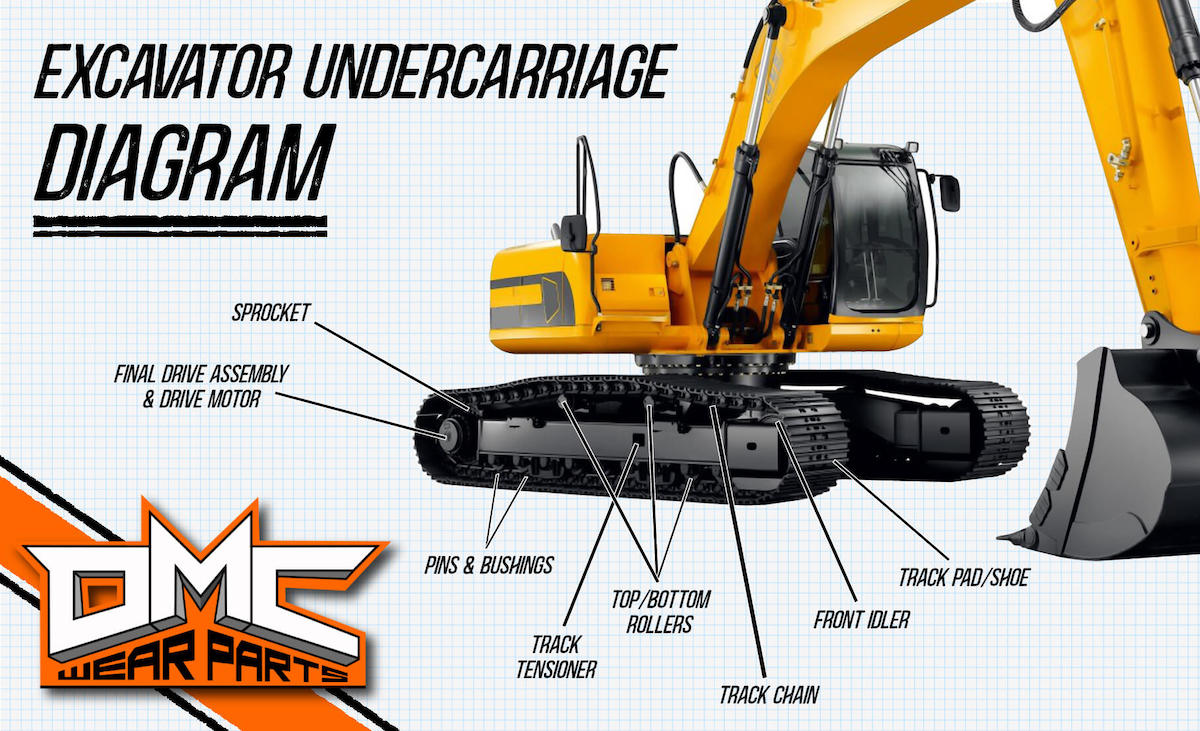

Utilizing sturdy undercarriage parts not only improves the longevity of hefty equipment yet also minimizes upkeep prices considerably. By purchasing premium undercarriage elements, such as tracks, idlers, rollers, and gears, devices drivers can experience enhanced uptime and boosted general performance.

Additionally, the durability of heavy equipment is directly connected to the high quality of its undercarriage components. Resilient parts can hold up against the rigors of demanding applications, making sure that the tools continues to be operational for prolonged periods. Because of this, drivers can prevent expensive downtime and maintenance costs, ultimately optimizing the return on financial investment for their equipment.

Elements Influencing Undercarriage Toughness

The longevity of undercarriage components in heavy machinery is affected by various important factors that straight influence performance and longevity. Among the essential factors influencing undercarriage sturdiness is the quality of products used in manufacturing. High-quality products, such as solidified steel, are vital for standing up to the severe problems and hefty tons that undercarriage parts are subjected to. Proper upkeep techniques additionally play a critical function in figuring out the lifespan of undercarriage elements. Normal evaluations, lubrication, and timely replacement of worn-out components can substantially expand the sturdiness of the undercarriage.

In addition, environmental aspects can have a considerable effect on the long life of undercarriage components. Exposure to unpleasant products, extreme temperature levels, and extreme working conditions can accelerate damage on undercarriage components. Choosing undercarriage components that are particularly developed to endure these ecological obstacles is crucial for making sure durability.

Additionally, the layout and design of undercarriage parts have a straight influence on their sturdiness. Parts that are created to disperse loads evenly, minimize friction, and minimize stress and anxiety focus are more probable to have a much longer life expectancy - undercarriage parts. By taking into consideration these critical factors, equipment drivers can optimize the toughness and performance of their undercarriage parts

Maintenance Tips for Lengthening Undercarriage Life

Carrying out regular maintenance routines is crucial for expanding the life-span of undercarriage parts in heavy machinery. To extend the undercarriage life, it is important to regularly inspect for deterioration. Consistently look for missing or loose bolts, harmed rollers, or misaligned tracks, as these issues can escalate and cause further damage if not resolved promptly. Additionally, make sure that the undercarriage is effectively lubricated according to supplier standards to minimize friction and avoid early look what i found wear.

One more essential upkeep tip is to keep the undercarriage tidy from dust, rocks, and debris. Buildup in the undercarriage can accelerate wear and deterioration, bring about expensive repair services. Cleaning the undercarriage after operation in rough conditions is advised to prevent these issues.

Finally, monitoring and recording maintenance tasks can assist in creating a positive upkeep schedule. Keeping in-depth records of repair work, examinations, and replacements can provide useful understandings right into the undercarriage's condition and performance over time, assisting in predicting and protecting against potential failures. By adhering to these upkeep tips vigilantly, drivers look at this site can substantially raise the sturdiness and performance of undercarriage parts in hefty machinery.

Picking the Right Undercarriage Components

Picking appropriate undercarriage elements is important for optimizing the performance and durability of hefty machinery. When it comes to selecting the best undercarriage components, there are numerous variables to take into consideration.

Furthermore, taking into consideration the high quality and online reputation of the producer is important. Choosing respectable brand names known for creating long lasting and high-performance undercarriage parts can significantly affect the overall performance and longevity of the machinery. Furthermore, making certain that the components work with the maker version and correctly mounted is crucial for optimum performance. By carefully choosing the ideal undercarriage parts, equipment proprietors can improve performance, minimize downtime, and expand the life-span of their heavy machinery.

Study: Improved Performance With Long Lasting Parts

Including durable undercarriage parts has actually shown considerable enhancements in machinery efficiency. One case research study included a construction firm that upgraded its excavator's undercarriage parts to extra long lasting choices.

In another instance, a mining operation changed the undercarriage parts of its excavator with high-grade, long lasting choices. This button brought about an impressive renovation in the excavator's maneuverability and total performance. The machine might browse challenging terrains extra effectively, leading to boosted operational performance and lowered gas usage.

In addition, a logging firm bought durable undercarriage parts for its forestry devices. The updated parts displayed long term life-span and raised resistance to abrasion from learn the facts here now rough terrain. The firm experienced lowered maintenance prices and better tools uptime, ultimately enhancing its bottom line. These situation studies emphasize the substantial advantages of making use of durable undercarriage components in maximizing machinery efficiency and longevity.

Final Thought

In verdict, using sturdy undercarriage parts can substantially boost performance and durability of heavy machinery. Elements such as appropriate maintenance and selecting the right components play a crucial function in making best use of undercarriage longevity. By applying these strategies, services can lower downtime, boost effectiveness, and inevitably reduce functional expenses. Case research studies have revealed that buying long lasting undercarriage parts can bring about enhanced total efficiency and performance in numerous industries.

The effectiveness and performance of these parts can substantially influence the total procedure of equipment, making the selection of sturdy undercarriage components a crucial choice for operators and managers alike.Integrating durable undercarriage parts has actually shown significant improvements in machinery efficiency. These situation studies highlight the tangible benefits of making use of long lasting undercarriage parts in maximizing equipment efficiency and durability.

In verdict, utilizing resilient undercarriage components can dramatically boost efficiency and longevity of heavy equipment (undercarriage parts). Instance studies have actually shown that spending in long lasting undercarriage components can lead to improved overall performance and performance in different markets

Report this page